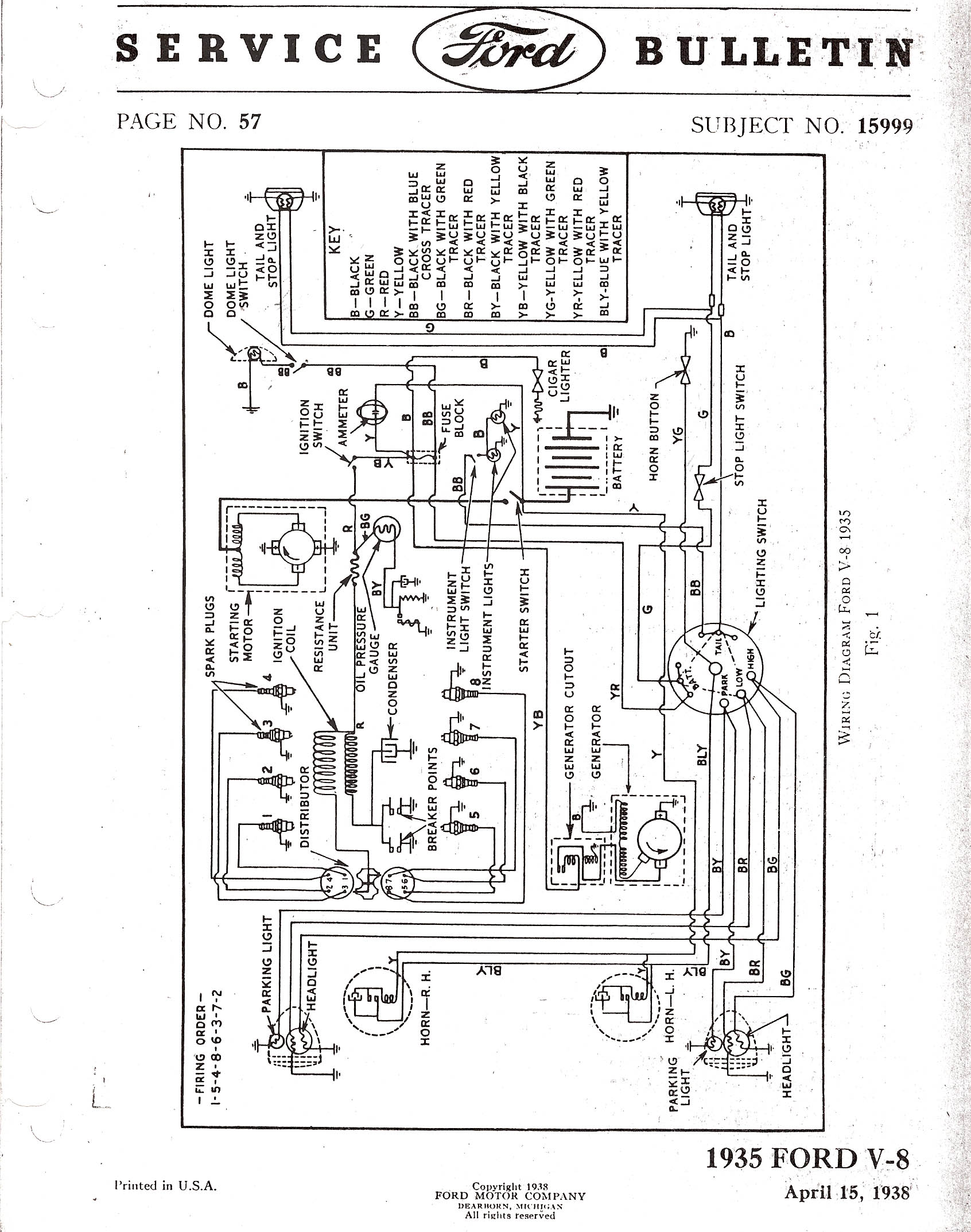

1935 Ford Wiring Diagrams are essential tools for any mechanic or car enthusiast working on a vintage Ford vehicle. These diagrams provide a visual representation of the electrical system in the vehicle, showing the connections between various components such as the battery, starter, alternator, lights, and more.

Why are 1935 Ford Wiring Diagrams essential?

- Helps in understanding the layout of the electrical system

- Aids in diagnosing and repairing electrical issues

- Ensures proper installation of new components

- Prevents electrical shorts and other safety hazards

How to read and interpret 1935 Ford Wiring Diagrams effectively

When looking at a wiring diagram for a 1935 Ford vehicle, it’s important to understand the symbols and colors used to represent different components and connections. Here are some tips to help you read and interpret the diagram:

- Refer to the legend or key to understand the symbols used

- Follow the flow of the electrical circuits from the battery to the components

- Pay attention to color-coding for different wires and connections

- Identify any fuses or relays in the diagram

Using 1935 Ford Wiring Diagrams for troubleshooting electrical problems

Wiring diagrams can be invaluable when troubleshooting electrical issues in a 1935 Ford vehicle. By following the wiring diagram and tracing the connections, you can pinpoint the source of the problem and make the necessary repairs. Here’s how you can use the diagram for troubleshooting:

- Check for continuity in wires using a multimeter

- Identify any loose or corroded connections

- Test components such as relays and switches for proper operation

- Refer to the wiring diagram to ensure components are connected correctly

Importance of safety when working with electrical systems

Working with electrical systems can be dangerous if proper precautions are not taken. When using wiring diagrams for any vehicle, including a 1935 Ford, it’s important to follow these safety tips:

- Always disconnect the battery before working on the electrical system

- Avoid working on the electrical system in wet or damp conditions

- Use insulated tools to prevent electrical shocks

- Double-check all connections before reassembling components

1935 Ford Wiring Diagram

Ford Truck Wiring Diagrams 1935 | Flathead Electrical Wiring Diagrams

Early Ford V-8 Club Forum

Headlight Taillight Wiring for 1935-36 Ford Trucks and Cars | Dennis

1935 Ford Ignition Wiring Diagram

1935 Ford Ignition Wiring Diagram

1935 Ford Ignition Wiring Diagram